Are you ready to build your own unmanned aerial vehicle? With this design tool, you may one day get your chance.

If you're not satisfied with any of the drones on the market, you may one day be able to design your own, thanks to researchers at the Massachusetts Institute of Technology.

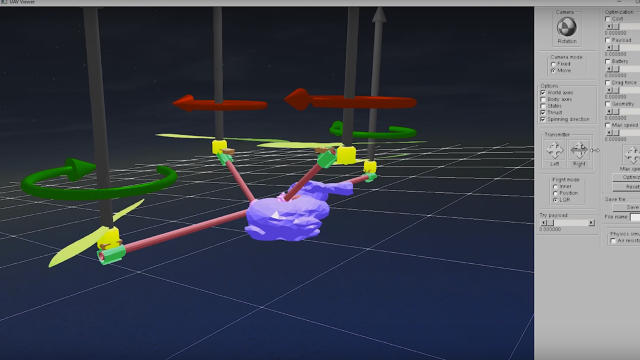

A team from MIT's Computer Science and Artificial Intelligence Laboratory has created a software tool that allows even relative novices to drag and drop standard components—including propellers, support rods, and a range of core body frames—and craft their own drone designs. While the database is relatively small, users of the tool can compose and manipulate the components to create a widely diverse set of designs, according to a paper the team plans to present this week at the SIGGRAPH Asia Conference in Macao.

Once users finalize their designs, the program automatically adjusts it for user-selected features such as battery life and maximum carrying capacity, tweaking factors like the overall shape and the angle and spinning directions of each propeller.

"We will try to do some optimizations to replace the rotors, or change the angles, or resize the rods so we can meet the requirements of the users," Tao Du, one of the paper's authors and a graduate student in the Computational Fabrication Group, tells Fast Company.

The team developed an efficient algorithm that lets the optimizations generally finish within a few seconds, according to the paper, though the results can differ dramatically: In one case, the optimized version could carry 30% more weight than the initial concept.

The group was able to create some whimsical designs, including some eye-catching models with odd numbers of propellers and even a design with a frame based on the Stanford bunny—a 3D rabbit image widely used in computer graphics demos.

But Du says the program could have more practical applications than whimsy. The group developed the tool after observing that doing tasks like carrying unusually shaped objects, or making sure onboard camera lenses aren't obscured by a drone's rotating propellers, can be a challenge with off-the-shelf models, he says. The hope is that custom drone design could one day aid in the creation of unmanned aerial vehicles that can carry specialized payloads.

Once the custom design is optimized, users can test it in a simple flight simulator, flying the drone with an emulated controller to see how it feels. If it isn't quite what they had in mind, they can go back to the virtual drawing board for another try. The simulation is relatively simple and doesn't capture all of the aerodynamical effects that might affect a particularly fast-flying drone, but it works reasonably well for slow-moving copters, according to the paper.

In testing, the team 3D-printed some of the controllers used to attach parts like motors and propellers—which have to be installed at custom angles output by the optimization engine—and put together the drones with the parts selected from the program's database.

"Most of the parts are pretty standard off the shelf, like motors, propellers, and batteries," Du says, adding that someone with even moderate engineering ability should be able to put together the parts.

Unfortunately for aspiring DIY drone designers, the team doesn't have any immediate plans to commercialize or otherwise release the product. But here's the good news: They may release an open-source version sometime in the future.